QUALITY CONTROL

Machining Technology is committed to providing quality products and services shipped on time that meet or exceed our customer’s specifications. We will accomplish this through our commitment to continually improve the effectiveness of our quality management system, services, and processes. Every order gets supported by strong quality control processes that our operators monitor consistently on the job. Our quality control professionals approve final product releases.

DESIGN REVIEW

There is a design review meeting for each order received before production starts. The team is made up of design, engineering, programming, manufacturing, and quality members. This assures that everybody involved in the successful completion of the order is aware of what needs to be accomplished.

INSPECTION EQUIPMENT

- CMM Zeiss Duramax (2019)

- CMM Zeiss Eclipse (2015)

- Oasis Core X2 Vision System (2018)

- Microvue Vertex Vision System (2017)

- Granite inspection surface plates

- 2 Optical Comparator .0001 resolution (2016)

- Hardness tester

- Mitutoyo Model P2-321 Toolmakers Microscope, 4″ x 8″ Travels, 2-Axis Digital Readouts

- Wilson Model 4RB Rockwell Hardness Tester

- Profilometers

All inspection equipment is calibrated and certified, traceable to the NIST.

Latest Projects

Show More

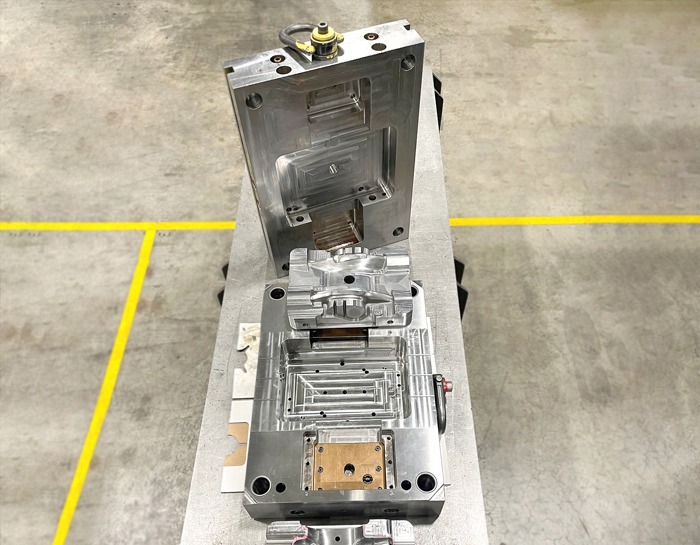

Pictured above is another job that the repair/revision team at Machining Technology is working on. This job involves a mold that was originally cut in the solid and a major part revision required cutting pockets and making inserts to fit the existing mold base. The new inserts were also made to shut off on existing slide faces so that it is entirely compatible with the existing base.

Show More

At Machining Technology, we take on the small jobs too! Our customer had multiple threaded pick-outs that had thread damage in need of repair. The thread damage was laser welded, and here our toolmaker is hand working the threads back to functional production condition by diamond filing and stoning the weld. If you require any mold repair or revision, Machining Technology would be delighted to work with you to update your molds to current revision levels or repair any damage that impairs the production of quality parts for your customer.

Show More

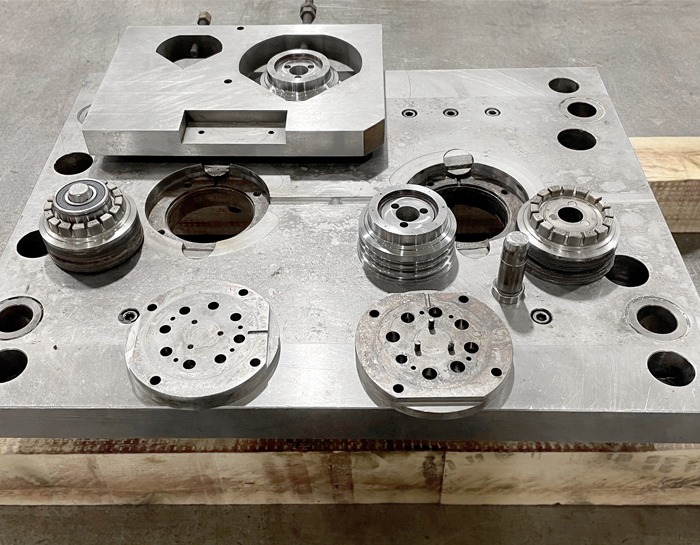

Here is another example of a job that the repair/revision team at Machining Technology is working on. The hardened cores on this customer’s tool are worn and need replacing to pass the part qualification process. We rough turned, heat-treated, and finish turned the cores after heat treat. The cores got hole popped and wired for multiple gate drops and will now get the core detail added by sinker EDM prior to polish. We will then fit the cores in the existing mold plate after the cores have gone through our quality department for the final inspection.