OUR HISTORY

In 2013, Machining Technology’s current owners bought a machine shop called Main-Tool that had over 35 years of experience in machining parts for a variety of industrial customers. Within 12 months, we enhanced the company by acquiring several new CNCs, hired additional professional and experienced operators, received ISO 9001 certification, moved to a larger building in Fridley, MN, and renamed it Machining Technology. We have been consistently pursuing to master the art of competitive manufacturing in the USA.

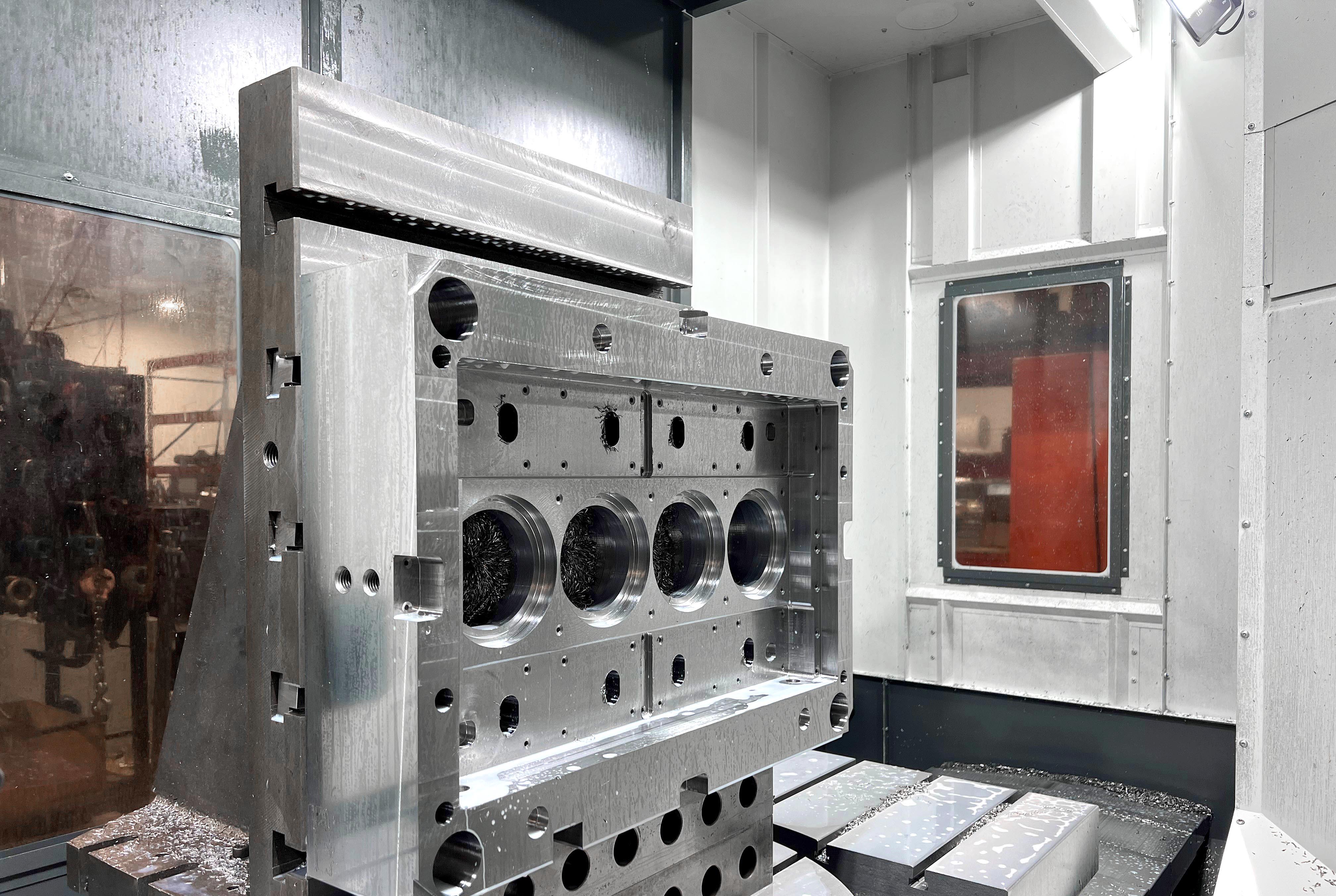

In 2020, we acquired the assets of Tooling Science, which have specialized in the design and manufacturing of die-cast and plastic injection molds since 1973. The aquisition brought us a team of professionals, including toolmakers, designers, and programmers who have a passion for designing and building new molds. They also have the capability to troubleshoot and help you solve problems related to your existing molds.

WHO WE ARE

Our dynamic, innovative, and experienced team assures that you can successfully choose Machining Technology as your manufacturing partner for all your manufacturing needs. We currently operate a large variety of milling, turning, swiss, and CNC EDM’s. We offer plating, heat-treating, welding, and painting services. Here at Machining Technology, we can machine multiple materials such as carbon steel, stainless, castings, aluminum, brass, and plastics. Our operators get supported by robust processes, lean manufacturing tools, and strict quality control protocols. Your part, component, assembly, or mold will be given the attention it deserves. Every process chosen for its production will be cost-effective, time-sensitive, and quality-assured.

At Machining Technology, we staff an independent repair and revision group with reliable equipment to ensure a quick and efficient turnaround. We will work with you to provide timely solutions for your current production tool issues. We offer plastic injection and die-cast molds and revisions, including mold design and engineering services. At Machining Technology, we will also take your overseas molds for revision, repair, and maintenance services.

Only the Best

OUR TEAM

Our people are our greatest asset. A culture built on collaboration, teamwork, and learning has allowed us to build a high-performing company. Machining Technology is an ISO-certified fast-growing company that offers excellent career opportunities in multiple disciplines.

OUR QUALITY

Machining Technology is committed to providing quality products and services shipped on time that meets or exceeds our customer’s specifications. We will accomplish this through our commitment to continually improve the effectiveness of our quality management system, services, and processes.

OUR BRAND

Our reputation for innovative, cost-effective solutions with quick turnaround has made us a premier supplier for many customers. Your part, component, assembly, or mold will be given the utmost attention. Everything we do is measured and analyzed for one purpose: our mutual success.