CHOOSE MACHINING TECHNOLOGY AS YOUR MANUFACTURING PARTNER

Welcome to Machining Technology – your premier source for high-quality machined products and services. As an ISO-certified, rapidly growing company, we are dedicated to exceeding our customers’ specifications. Our machining capabilities are extensive and include production CNC milling, CNC turning/swiss, and EDM applications. Moreover, we specialize in designing, manufacturing, and repairing die-cast and plastic injection molds. From small intricate parts to complete molds, Machining Technology is your one-stop solution. Choose Machining Technology for superior machined solutions that meet and surpass industry standards. Experience the difference in quality with our expert team and state-of-the-art technology.

CNC MILLING

Our diverse state-of-the-art machine variety allows us to select the most ideal machine for your needs. Machining Technology’s CNC milling department is comprised of both vertical and horizontal machining centers capable of producing parts up to 100” in length and 52” in width.

CNC TURNING & SWISS

Machining Technology’s CNC turning department consists of both standard and Swiss lathes. Our machining centers can produce small parts and large parts up to 69” in diameter.

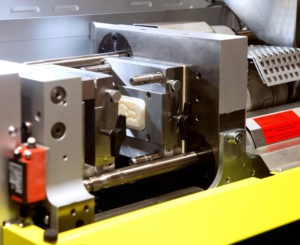

CNC EDM, SINKER & WIRE

Machining Technology offers complete CNC EDM services, sinker type, and wire cutting. Whether used as complementary services to complete a production machining process that machining alone can’t achieve or for stand-alone production, we can provide the expertise to finish the job.

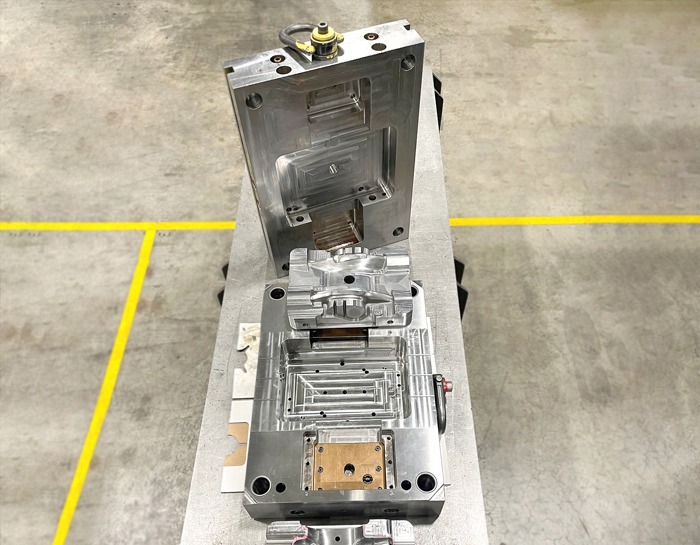

DIE-CAST MOLDS

Machining Technology proudly employs a very experienced and diverse team of mold design and manufacturing specialists. We also offer repair and revision services through a dedicated team experienced with the specific knowledge to complete your job promptly, optimally, and with the quality standards you expect.

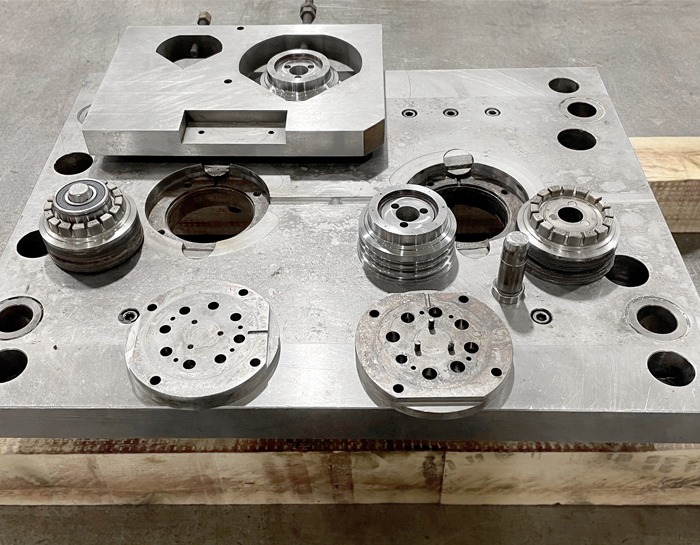

PLASTIC INJECTION MOLDS

We operate a variety of modern and state of the art equipment, including CNC mills, turning centers, and CNC EDM’s both wire and sinker. Machining Technology offers in-house deep hole gun drilling for your various plate requirements. We utilize multiple Roku-Roku vertical high-speed graphite mills (30,000 RPM) to precisely cut EDM electrodes to provide clean and accurate burning of part details and mold shut-offs.

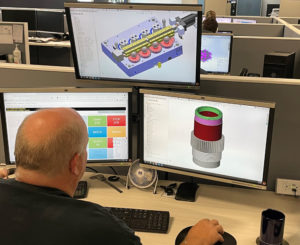

MOLD DESIGN & ENGINEERING

Machining Technology’s diverse staff is experienced in designing and manufacturing molds, prototypes, bridges and production, DFM of parts, mold troubleshooting, EOAT(end of arm tooling), and fixtures. Our 45 years of experience provide a foundation of knowledge to solve all mold challenges. When you choose Machining Technology, you’ll access complete 3D design protocols.

Years In Business

our people

Our people are not just employees; they are our greatest assets. Building on collaboration, teamwork, and continuous learning, our thriving culture sets the foundation for a high-performing company. Our commitment to excellence extends to continually enhancing the effectiveness of our quality management system, services, and processes.

CAREERS

Explore exciting career opportunities across various disciplines, with a special focus on CNC programmers and operators. At Machining Technology, we offer not only a stimulating work environment but also a highly competitive pay and benefits package to support your professional growth. Join us and be part of a workplace that champions diversity and equality. As an equal employment opportunity company, we celebrate a workforce that thrives on unique perspectives and talents. Embark on your journey with Machining Technology – where your skills meet endless possibilities.

Latest Projects

Show More

Pictured above is another job that the repair/revision team at Machining Technology is working on. This job involves a mold that was originally cut in the solid and a major part revision required cutting pockets and making inserts to fit the existing mold base. The new inserts were also made to shut off on existing slide faces so that it is entirely compatible with the existing base.

Show More

At Machining Technology, we take on the small jobs too! Our customer had multiple threaded pick-outs that had thread damage in need of repair. The thread damage was laser welded, and here our toolmaker is hand working the threads back to functional production condition by diamond filing and stoning the weld. If you require any mold repair or revision, Machining Technology would be delighted to work with you to update your molds to current revision levels or repair any damage that impairs the production of quality parts for your customer.

Show More

Here is another example of a job that the repair/revision team at Machining Technology is working on. The hardened cores on this customer’s tool are worn and need replacing to pass the part qualification process. We rough turned, heat-treated, and finish turned the cores after heat treat. The cores got hole popped and wired for multiple gate drops and will now get the core detail added by sinker EDM prior to polish. We will then fit the cores in the existing mold plate after the cores have gone through our quality department for the final inspection.